Trugen Machinery offers services including production line layout planning, installation & commissioning and spare parts supplying to solve the challenges faced by corrugated cardboard and carton manufacturers, helping them achieve high efficiency production which translates to better productivity.

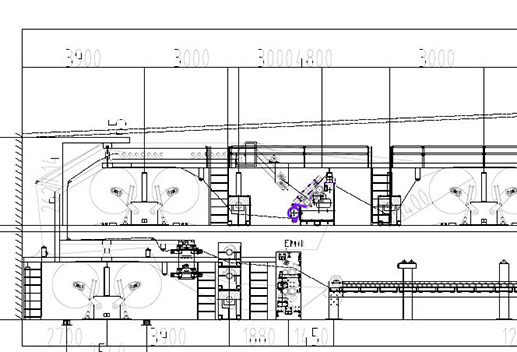

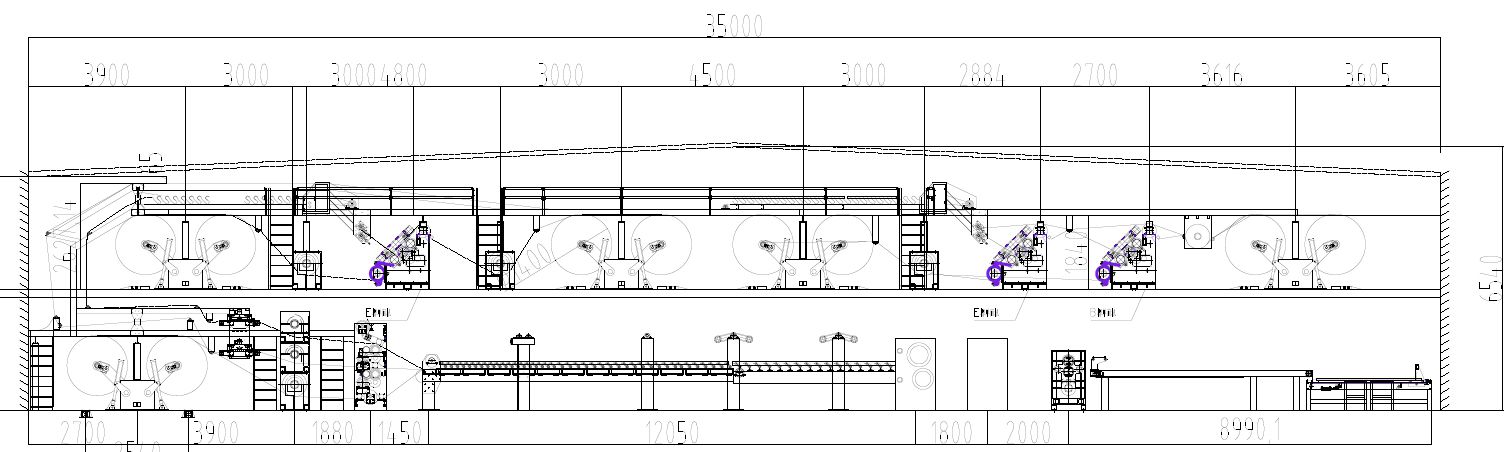

Production Line Layout Planning Service

Based on the working areas within customer's manufacturing plant, we can provide a modified version of production line to adapt to the plant. When customer's factory is limited in space, we will do appropriate modifications on production line configurations to minimize the space consuming without compromising on production efficiency. If the workshop has sufficient space in height, we can construct a double-deck production line to optimize the space utilization rate.

The corrugated cardboard production line will be custom-configured to accommodate the conditions of customer's existing workshop, aiming at assisting operators in machine controlling. Such as, the facing direction of machine control system can be designed according to operator's preference.

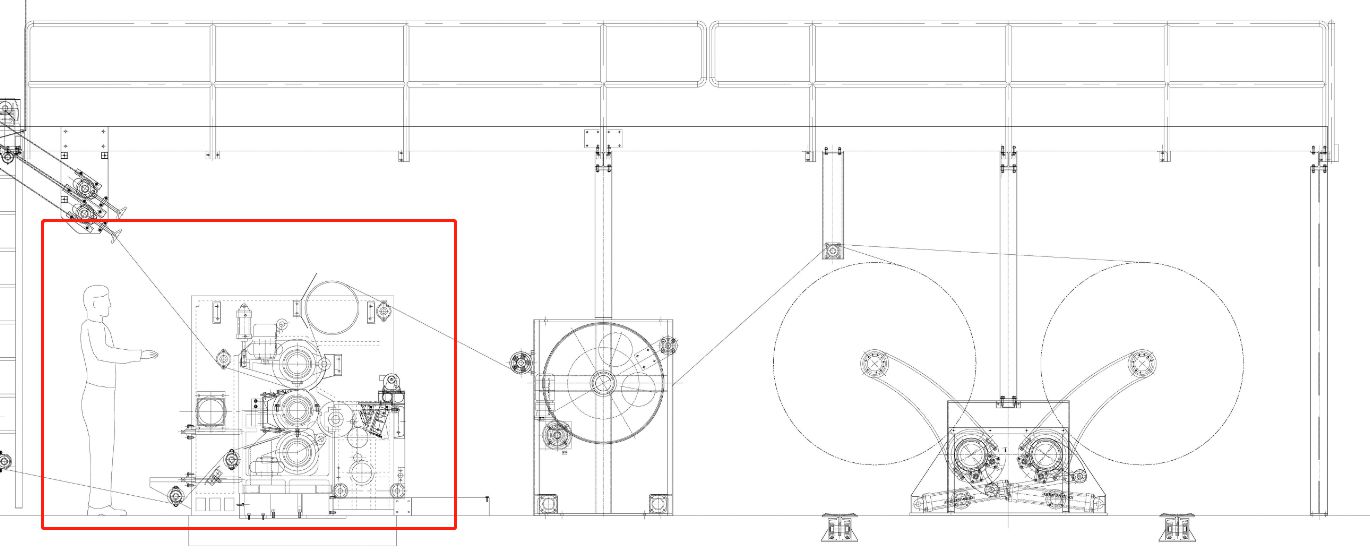

Case 1

- Customer country: Argentina

- Cooperation time: 2018

- This customer is a 3-ply corrugated board manufacturer in Argentina, they have a small workshop where space is not enough to place a standard production line. With that in mind, we made a modification on equipment configurations without sacrificing the production efficiency. As a result, the corrugated board equipment has been perfectly installed, and the production efficiency has been significantly improved.

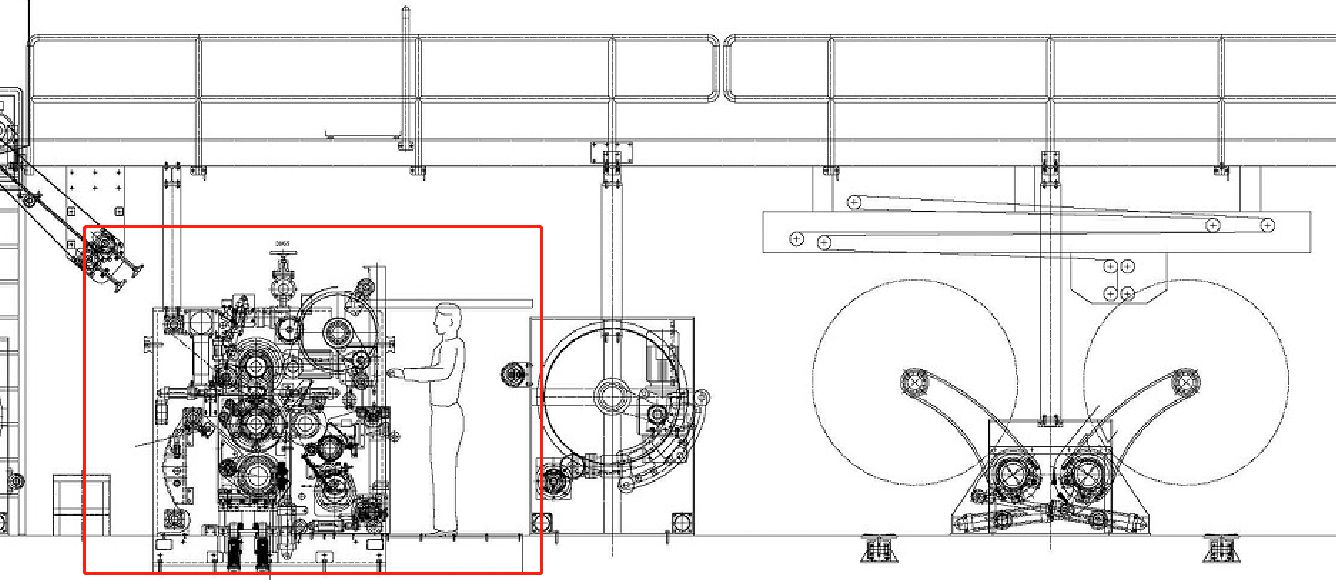

Case 2

- Customer country: Mexico

- Cooperation time: 2020

- This customer is a 3-ply corrugated board manufacturer in Mexico. They came to us for a corrugated cardboard production line with double-deck structure to place in their double-story factory. Based on their request, we have remodeled the factory by opening up some areas of the second floor, thus connecting the equipment placed at two floors to form a double-deck corrugated cardboard production line. During the period of machine installation, our mechanical installation engineer and electrical engineer have provided on-site service. The entire installation period took only 14 days.

-

Corrugator – Auto Splicer

- Splicing speed: 0-150m (5905.51")/min (depending on paper quality)

- Splicing time: approximately 1 second

- Working speed: 0-200m (7874.02")/min

- Paper weight: 90-320g/m2

-

-

Corrugator – Single Facer

- Max. design speed: 150m (5905.51")/min

- Working width: 1600mm(62.99"), 1800mm(70.87")

- Heat source: steam

-

-

Corrugator – Preheater

- Preheat roll diameter: 600mm(23.62"), 800mm(31.50"), 900mm(35.43"), 1000mm(39.37"), 1100mm(43.31")

- Wrap angle: 320 degree

-

-

Corrugator – Mill Roll Stand

- Movement of roll stand arm: fully hydraulic motion

- Paper roll diameter: max. φ1500mm, min. φ400mm

- Spindle diameter: φ240mm

-

-

Corrugator – Glue Machine

- Design speed: 150m(5905.51")/min

- Working width: 1800mm(70.87"), 2000mm(78.74"), 2200mm(86.61"), 2500mm(98.43")

-

-

Corrugator Bridge

- Design speed: 100m(3937.01")/min-250m(9842.52")/min

- Guide precision: ±3mm (0.12")

-

-

Corrugator – Double Facer

- Design speed: 100m (3937.01")/min-250m (9842.52")/min

- Working width: 1800mm (70.87"), 2000mm (78.74"), 2200mm (86.61"), 2500mm (98.43")

-

-

Corrugator – Slitter Scorer

- Trugen Machinery can supply various models of corrugated board slitting and scoring machines to help you cut cardboards to exact sizes and crease fold lines that enable cartons and boxes to be easily folded.

-

-

Cutting Machine

- High-precision cardboard cutting machine designed for fast, stable, and accurate sheet cutting. Features durable construction, smooth operation, and intelligent control for packaging, printing, and converting applications.

-

-

Corrugator – Stacker

- Design speed: 250m (9842.52")/min

- Working width: 1800mm (70.87"), 2000mm (78.74"), 2200mm(86.61"), 2500mm(98.43")

- Stacking height: 1800mm (70.87")

-

-

Corrugator – Cutting and Stacking System

- Machine speed: 100m (3937.01")/min

- Recommended speed: 60-90m (2362.20-3543.31")/min

- Stacked cardboard length: 300-1600mm (11.81-62.99")

-