Stitcher Folder Gluer

Corrugated Box Automatic Folding Stitching and Gluing Machine

Features

- Statistics regulation, synchronous running of two variable frequency convertor, possessing easy, quick and reliable manipulation mode;

- Computer-controlled and easy and convenient order switch;

- PLC-controlled system and touch screen are designed for convenient operation;

- Automatic paper feeding, glue folding, counting and stacking, average speed at 150 meters/min, high-efficient, energy-saving and labor cost saving;

- Three, five and seven layers of corrugated board are available(seven layers specified)

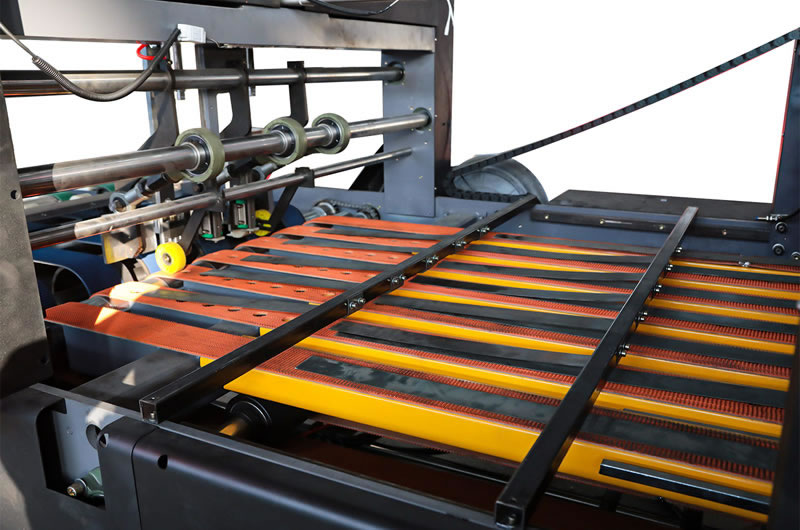

Paper feeding unit

- Adjustable height of scoring wheel, suitable for 2-8mm cardboard;

- Belt lead edge absorbs air flow to feed paper, accurate and reliable;

- High-end electromagnetic clutch and brake system, individually controlled, easy and reliable operation;

- Front baffle and conveying belt of paper feeding unit are adjustable.

- Lead edge paper feeding via vacuum absorption, ensuring the straightness of carton.

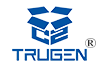

Folder gluer unit

- Imported belt conveyor with strong friction force which can achieve automatic folded transmission;

- Gluing on stainless wheel to well distribute glue quantity, free of failure and saving glue;

- Folder unit is equipped with paperboard and scoring guiding device;

- Two rows of inner adjustable positioning guide rollers are equipped to ensure the right paperboard scoring place;

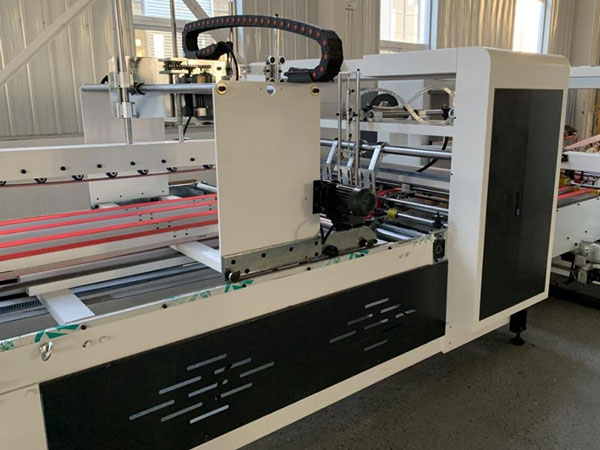

Counting stacking unit

- Main powering motor speed regulation of variable frequency and stable and reliable booting;

- Belts are designed to transmit cardboard, orderly stacking, speed controlling ranging from 0-130 M/MIN;

- Bottom belt along with upper pressing belt synchronously reinforcing pressure, ensuring enhanced sticking and perfect matching of finished products;

- Stacking height at 8-25 pieces of paper;

- Arbitrarily adjusting nail distance from 30-100mm.

- Single nail, duplex nail and automatically switchable nail are available which can meet various needs of different clients;

- Few minutes are enough to switch carton’s dimension and nail distance which greatly saves time and is convenient for manipulation.

Packing unit

- Individually working, or synchronously working with automatic nail stitching box machine. Step-on or manual control in individual working process, detecting probe is forbidden, extruding line is needed when synchronously working with nail stitching box machine, automatic bundling when getting through detecting probe.

- Duplex laminating to conduct automatic bundling, fuse packing belt width 5-6mm.

Technical specifications

| Stitching unit | Max./mm | 3000x1600mm |

| Min./mm | 800×300mm | |

| Design speed | 200m/min | |

| Stacking height | 400mm | |

| Nailing unit | Max./mm | 3000×1600mm |

| Min./mm | 880×300mm | |

| Design speed | 750nails/min | |

| Nail distance | 30-100mm | |

| Length | 200-900mm | |

| Width | 200-500mm | |

| Min. height | 120mm |

Get in Touch

Trugen Machinery has been dedicated to manufacturing and supplying complete corrugator systems for paper and corrugated packaging industries since its foundation. As a specialist corrugating machinery manufacturer, manufacturing corrugator and converting equipment for corrugated carton manufacturers and cardboard box suppliers is only a part of what we do. We are also able to offer a comprehensive range of services from plant layout design to repair and upgrade of your paper corrugation machines, corrugated board converting machines or corrugated box making machines. Our specialist competence makes us capable of providing individual machines for various corrugated manufacturing process. Trugen Machinery is looking forward to continuing our respected reputation in corrugated market.