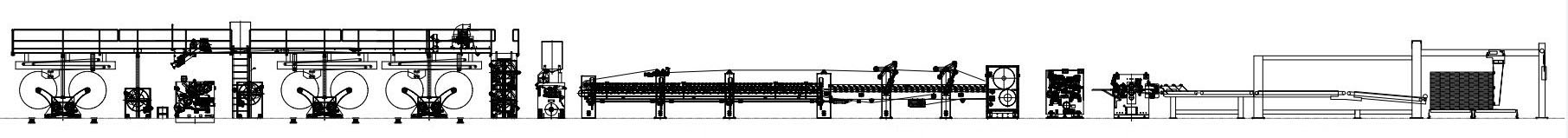

Single Facer with 2 Corrugating Rolls, SF-HW15

Corrugated Board Manufacturing

-

- Max. design speed

- 10m (393.70")/min

-

- Working width

- 1400mm (55.12"), 1600mm (62.99"), 1800mm (70.87")

-

- Heat source

- steam, electricity, liquid gas

-

- Diameter of corrugating roll

- 320mm (12.60")

Features

- This unit is designed with two sets of corrugating rolls, when one set is in operation, other one is in pre-heating, thus ensuring quick change and ease of maintenance;

- The corrugating section is separated from glue application section, providing great convenience for corrugating roll assembly and disassembly;

- Paper feeding is carried out by using vacuum absorption method, ensuring a stable corrugation process;

- Automatic glue feeding, automatic control of glue quantity with digital readout;

- Hydraulic pressure control, pneumatic control of glue application and return, guaranteeing safe operation;

- Corrugating rolls are made of 48CrMo alloy steel, hardened with quenching process (hardness HRC55-58), and plated with hard chrome for longer service life;

- This system is configured with 2 sets of glue application system and 2 sets of corrugating roll system;

Get in Touch

Trugen Machinery has been dedicated to manufacturing and supplying complete corrugator systems for paper and corrugated packaging industries since its foundation. As a specialist corrugating machinery manufacturer, manufacturing corrugator and converting equipment for corrugated carton manufacturers and cardboard box suppliers is only a part of what we do. We are also able to offer a comprehensive range of services from plant layout design to repair and upgrade of your paper corrugation machines, corrugated board converting machines or corrugated box making machines. Our specialist competence makes us capable of providing individual machines for various corrugated manufacturing process. Trugen Machinery is looking forward to continuing our respected reputation in corrugated market.