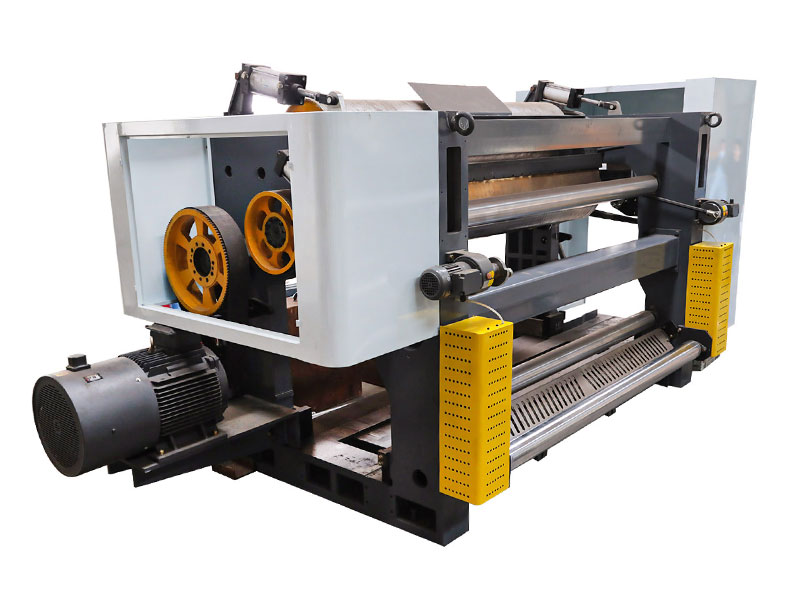

Single Facer with Cassette, 280

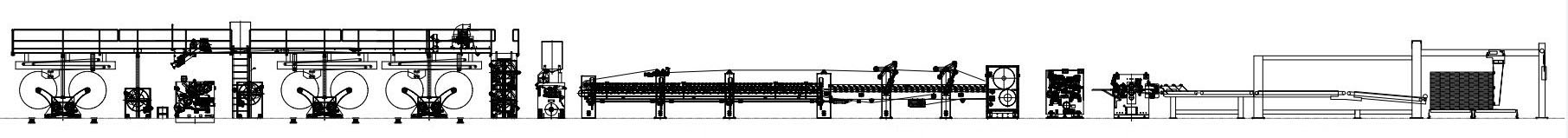

Corrugated Board Manufacturing

| Design speed | 100m/min |

| Working speed | 80m/min |

| Temperature range | 160-200°C |

| Steam pressure | 0.8-1.3Mpa |

| Air pressure | 0.4-0.9MPa |

| Flute type | (UV or UVV) |

| Corrugator Roll Dia. | Ø280mm |

Features

- Tungsten carbide or alloy steel can be used as the material of corrugator roll;

- Cassette type single facer provides quick flute change;

- Paper feeding is carried out by using vacuum absorption method, a high-pressure blower is equipped to ensure the stable corrugation process at high speed;

- The width of groove on lower corrugating roll is less than 2mm, efficiently preventing the marks of stripes on corrugated cardboard;

- Universal joint transmission system is adopted to reduce vibration, enabling the operation more stable and reliable;

- Reduction gearbox is designed with oil-immersed lubrication to lower the machine vibration;

- Automatic glue feeding, pneumatic control of glue application and return can provide cushion effect;

- Engraved glue applicator roll is chrome plated;

- Upper and lower corrugating rolls are made of 48CrMo high grade alloy steel;

Get in Touch

Trugen Machinery has been dedicated to manufacturing and supplying complete corrugator systems for paper and corrugated packaging industries since its foundation. As a specialist corrugating machinery manufacturer, manufacturing corrugator and converting equipment for corrugated carton manufacturers and cardboard box suppliers is only a part of what we do. We are also able to offer a comprehensive range of services from plant layout design to repair and upgrade of your paper corrugation machines, corrugated board converting machines or corrugated box making machines. Our specialist competence makes us capable of providing individual machines for various corrugated manufacturing process. Trugen Machinery is looking forward to continuing our respected reputation in corrugated market.