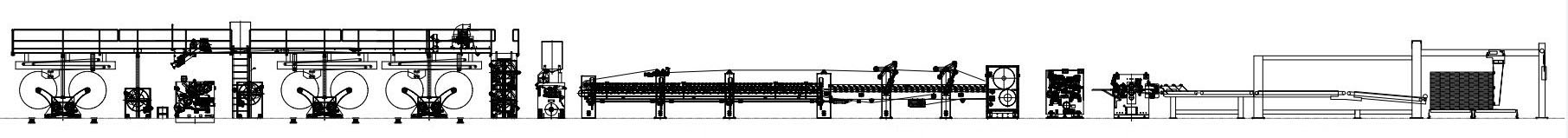

Automatic Slitter Scorer, 150/200/250m/min (QDD type)

Corrugated Board Manufacturing

Features

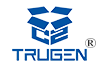

- Slitting blade and scoring wheel are controlled by independent motors, ensuring fast, precise and reliable operation;

- Variable frequency drive is used for control of slitting and scoring, speed can be synchronized with corrugating line;

- Two rows of scoring wheels achieve minimum scoring distance of 0mm;

- Three score profiles are available;

- Electric adjustment of scoring depth;

- Tungsten steel alloy blade is featured by long service life, automatic sharpening system is configured;

- Transverse movement control system is available;

- HMI touch screen for easy operation;

- Designed with standard interface to facilitate access to production management system;

- Up to 999 orders can be stored;

- Compact structure with less vibrations;

- Linear slider of high precision and grinding ball screw transmission, ensuring the positioning accuracy of slitting line.

- Automatically tracking the speed of manufacturing line to ensure their synchronizing and compatible with existing manufacturing administrative system.

- Automatic or manual sharpening controlled by the computer, lightweight and easy to maintain.

- Synchronous belt with high precision, low noise and long service life.

- Electric left and right guiding 200mm.

- Longitudinal knife and scoring wheel is respectively controlled by individual motor, 1-3 second order change and precision ± 0.5mm.

- Synchronous belt transmission with no gap and precise encoder monitoring.

- Imported branded components, ensuring the perfect running.

- Two machines can be alternately used, guaranteeing the continuity of slitting with no necessity of stopping machines.

Specifications

| Model | | | |

| Effective width | 1850mm(72.83") | 2250mm(88.58") | 2550(100.39") |

| Min. slitting | 135mm(5.31") | ||

| Min. scoring distance | 0mm | ||

| Slitting blade size | 260*158*1.3mm(10.24*6.22*0.05") | ||

| Scoring wheel size | Upper 162mm(6.38"),lower 162mm(6.38") | ||

| Order change (servo) | 1-3s | ||

| Guiding range | ±100mm(3.94") | ||

| Precision | ±0.5mm(0.020") | ||

| Slitting/scoring | 5/8 | 6/10 | 7/12 |

| Servo quantity | 14 | 28 | 33 | Power | 16kW | 20kW | 21kW |

| Dimension (pre-pressing type) | 3840*2100*2450mm (151.18*82.68*96.46") | 4240*2100*2450mm (166.93*82.68*96.46") | 4540*2100*2450mm (178.74*82.68*96.46") |

| Dimension (common type) | 3840*1720*2450mm (151.18*67.72*96.46") | 4240*1720*2450mm (166.93*67.72*96.46") | 4540*1720*2450mm (178.74*67.72*96.46") |

| Scoring depth | 12mm(0.47") | ||

| Speed (m/min) | 150/200/250m(5905.51/7874.02/9842.52")/min | ||

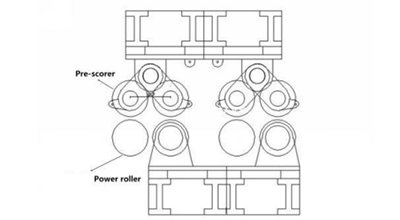

Pictures

Get in Touch

Trugen Machinery has been dedicated to manufacturing and supplying complete corrugator systems for paper and corrugated packaging industries since its foundation. As a specialist corrugating machinery manufacturer, manufacturing corrugator and converting equipment for corrugated carton manufacturers and cardboard box suppliers is only a part of what we do. We are also able to offer a comprehensive range of services from plant layout design to repair and upgrade of your paper corrugation machines, corrugated board converting machines or corrugated box making machines. Our specialist competence makes us capable of providing individual machines for various corrugated manufacturing process. Trugen Machinery is looking forward to continuing our respected reputation in corrugated market.