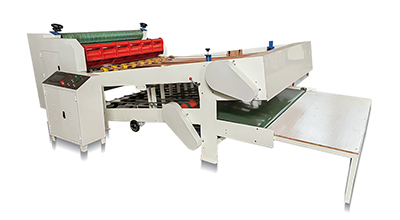

Single Corrugated Slitting Cutting and Stacking Machine,NCM-15D

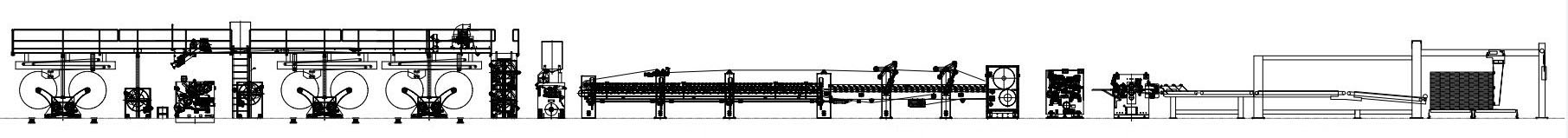

Corrugated Board Manufacturing

Specifications

-

- Machine speed

- 150m (5905.51”)/min

-

- Recommended speed

- 100m-120m(3937.01”-4724.4’’)/min

-

- Stacked cardboard length

- 300-1600mm (11.81-62.99")

-

- Cutting precision

- ±1mm (0.04")

-

- Max. stacking height

- 300mm (11.81")

Features

- The system consists of slitting unit, cut-off unit and stacking unit, single face corrugated sheets are cut to desired size and stacked to required quantities for downstream processes of sheet-to-sheet laminating and carton box stitching;

- Adopting tungsten metal alloy blade that features high sharpness, with service life of more than 8 million meters;

- Automatic or manual blade sharpening, cutting and sharpening can be carried out simultaneously for improved production efficiency;

- Cut-off unit is servo controlled;

- Upper and lower cut-off knife shafts are equipped with precise gear transmission system and automatic circulating oil cooling system, enhancing cutting precision;

- Helical cut-off knife system, easy and quick knife adjustment;

- 15" LCD control panel, machine running and stopping are controlled by button;

- Stacking can be pre-set according to required height or desired quantities, which are switchable according to actual production needs;

- Automatic sheet counting and stacking with non-stop operation, PLC controlled;

- Pneumatic cardboard lifting;

- Two rows of delivery table of 400mm in width are available for manual take-off;

- 999 sets of orders can be stored, automatic or manual order change without stopping the machine.

- Four stages of delivery with different purposes, the first stage separates single corrugated board, the second stage stacks tile-like single corrugated board, the third plus fourth stage stably transmit the board in second stage to stacker;

- Pointing and counting of single corrugated board is controlled by photoelectric switches. The combination of different delivery sections and stacking is controlled by PLC.

Get in Touch

Trugen Machinery has been dedicated to manufacturing and supplying complete corrugator systems for paper and corrugated packaging industries since its foundation. As a specialist corrugating machinery manufacturer, manufacturing corrugator and converting equipment for corrugated carton manufacturers and cardboard box suppliers is only a part of what we do. We are also able to offer a comprehensive range of services from plant layout design to repair and upgrade of your paper corrugation machines, corrugated board converting machines or corrugated box making machines. Our specialist competence makes us capable of providing individual machines for various corrugated manufacturing process. Trugen Machinery is looking forward to continuing our respected reputation in corrugated market.