Automatic Printing Folder Gluer

Paper feeding unit

- Paper feeding without pressing front edge, ensuring electrical paper feeding with no pressure;

- Compact design of double bellows, the lead edge and transmission unit is driven by gearbox which effectively guarantees linear speed of lead edge keeping consistent with the machine at 220 revolutions per minute;

- 7.5kW high pressure centrifugal fan which can adjust the airflow according to the warpage of cardboard, ensuring the smoothness of paper feeding;

- Left and right baffle are made of premium grinded and electroplated thickened steel, moving is electrically adjusted powered by tin bronze plus screw, equipped with paper tidiness managing function which enables people adjust tidiness managing time to meet the production of different papers;

- Premium anti-static brushes dust clearing function which can remove scraps of papers on the surface of cardboard and improve printing quality.

Printing unit

- Premium grinded and hard chrome-plated steel;

- Engrave baseline on roller at the horizontal and peripheral direction which is convenient for checking the edition;

- Printing phase is designed with precise planet device, arbitrary adjustment of machine closing and opening , PLC-controlled phase with the regulation precision reaching 0.1mm;

- Vacuum absorption transmission system, bellows designed with linear guide rail, specially processed porcelain conveyor wheel, stable conveying, imported bearing steel with great durability and high precision;

- Gap between pressing roller and paper guiding shaft of bridges designed with self-locking double-stage worm gear box, indexing, quick and convenient adjustment ranging from 0-10mm(inner slightly adjusting panel is convenient for regulating the parallel of two rollers);

- Wallboard bearings in each side of drive shaft and anilox roller can be lubricated to maintain, also equipped with oil adding device, thus extending bearing service life.

- Circulating of anilox roller’s automatic idle running, thus preventing drying of printing ink, automatic washing;

- Specially grinding of rubber roller, superior ink transfer, ensuring ink distributing quality;

- Steel tube surface is covered with wearable rubber possessing delicate texture and balanced ink scraping, acid and alkali resistant, durable service life;

- Vertically direct drive system free of belt and chain which can reduce mechanical power loss of the motor itself and error, noise and tightening incurred by connection, lower failure rate and safer maintenance;

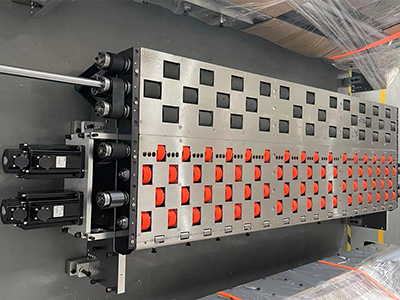

Slotting unit

- Precisely processed slotting cutter, two grinding of cutter shaft and chrome plated, stable moving;

- Automatic regulation of slotting cutter holder, scoring wheel and pre-pressure wheel’s axial displacement;

- Slotting gap, box height and dimension is controlled by PLC and rotary encoder, automatic adjustment;

- Single shaft slotting with two blades, box height is electrically regulated by internal gear to prevent lubricating oil’s pollution over cardboard. Box height adjustment is protected by digital anti-collision system, not damaging machine;

- Cutter holder traverse structure is designed with precise screw and linear guiding rail, flexible move and accurate positioning of cutter holder;

- Upper and lower cutter holder is interlocked by drive shaft, keeping the alignment of upper and lower blades during moving, thus extending service life of cutter;

- Precise gearbox with spiral bevel gear, seamless transmission,gaps are adjustable after several years’ using. Precise linear guiding rail and cross shaft converter are interacted to generate stable and accurate displacement. Higher transmission efficiency than traditional turbo box and gaps are adjustable.

Adhesive unit

- Adjustable gluing system with constant temperature, constant glue temperature, ensuring the best adhesion performance;

- Cave-like applicator wheels are designed to ensure stable gluing;

- Gluing unit is designed with servo gluing system to prevent glue solidification when the machine is in the interval;

- The gluing wheel gap is convenient for adjusting, equipped with dial to meet the gluing of 1.5-8mm papers, gluing quantity is convenient for adjusting, accurate digital glue spraying system.

Folding unit

- Lengthening high intensity folder box bridge arm supported by the medium high strength bridge bearing, speedy and stable;

- Precise linear guiding rail keeping synchronous with displacement system, accurate displacement;

- Elastic guiding rail pressing wheel, upper and lower belt gripping together to deliver;

- Unique folding guiding wheel system equipped with navigation pole, excellent folding quality;

- Back absorption type belt transmission, guiding device is driven by individual motors on both sides which can achieve effective guiding;

- Upper and lower belt keeping the same speed with printing machine, folding and conveying belt keeping nearly same speed with printing machine which can effectively prevent blurred boxplots from occupying paper or paper jam with printing machine and achieve more precise paper holding;

- Speed of upper and lower belt are individually adjustable. Their speeds can be adjusted to the same;

- Belt and rubber roller are adopted to fold paper which are convenient for regulating folding angle, easy operation.

Get in Touch

Trugen Machinery has been dedicated to manufacturing and supplying complete corrugator systems for paper and corrugated packaging industries since its foundation. As a specialist corrugating machinery manufacturer, manufacturing corrugator and converting equipment for corrugated carton manufacturers and cardboard box suppliers is only a part of what we do. We are also able to offer a comprehensive range of services from plant layout design to repair and upgrade of your paper corrugation machines, corrugated board converting machines or corrugated box making machines. Our specialist competence makes us capable of providing individual machines for various corrugated manufacturing process. Trugen Machinery is looking forward to continuing our respected reputation in corrugated market.